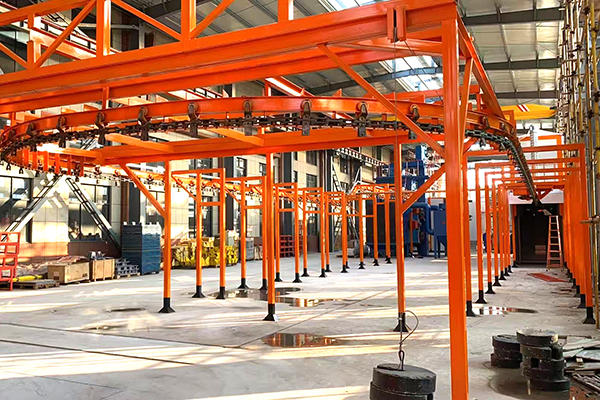

horizontal powder coating line manufacturer

Exported to more than 60 dünya çapında ülkeler

Meet different customer needs

The core advantages of horizontal powder coating line design

1、The pudra kaplama hattı process is uniquely designed, with high coating uniformity, no grooves, no impurities, no peeling, and stable quality.

2、The automatic powder coating system is highly efficient and reduces labor/time costs.

3、The powder coating reclaim system has a recovery rate of 98.9%, and the powder is recycled, which is environmentally friendly and energy-saving.

powder coating line price

Prices start at $6,000!

Powder coating line prices are determined by the following factors:

1、The maximum size of the workpiece:

determine the cross-sectional area size of the powder room and drying channel.

2、Weight of the workpiece:

determines the selection of the chain, light weight: 30, 50, 100 kg; Heavy duty: 250, 500 kg.

3、Output of spraying:

determines the length of the spraying line.

4、Standart dışı özelleştirme:

The price is determined according to the length, width, and height of the customer's factory, as well as whether the pre-treatment is online.

Danışmanız için teşekkür ederiz! Lütfen aşağıdaki formda aşağıdaki bilgileri sağlayın:

1) What’s the maximum & minimum size of workpiece( LxWxH)?

2) What’s the maximum weight of workpiece? If possible,youd better share us product photos.

3) How many workpiece do you want to paint per day( 8hrs or 16hrs ) or per month ?

4) What kind of heating energy do you prefer, such as electricity, diesel, oil, or natural gas?

5) What’s your workshop size LxWxH? May we have a drawing of your workshop?

6) Before painting, do you need spray pretreatment to clean the surface of product?

7) What’s the voltage & frequeny in your country?

Lütfen paylaşın Whatsapp veya diğer anlık araçlar daha zamanında iletişim için!

Fabrikamızı ziyaret etmek için dünyanın her yerinden hoş geldiniz arkadaşlar

Birden fazla modern atölyede 24,000 metrekare, standardizasyon tüm üretim hattından geçer.

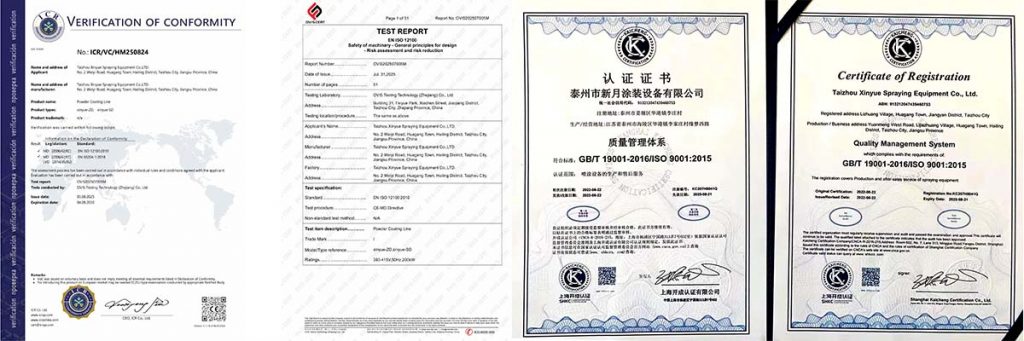

Başarılacak çoklu kalite kontrol testleri "üretim standartları, süreç izlenebilirliği, ve kalite güvencesi" yüksek kalite gereksinimlerini sağlamak için.

Sahibiz 33 Yılların sektör tecrübesi ve 100'den fazla ülkeye ihracat 60 dünya çapında ülkeler.

İtalyan mühendisler rehberlik için fabrikada görevlendirildi, birçok büyük işletmeye hizmet veriyor.

Kurumsal ruh:

bütünlük, minnettarlık, birlik, sıkı çalışma

Kurumsal misyon:

işlemi daha basit hale getirin ve boyamayı daha uygun maliyetli hale getirin

Kurumsal vizyon:

dünyanın güvenine layık bir Çin kaplama şirketi olmak!

Bize Ulaşın

Telefon:+0086-17802529388

Wechat:17802529388

Whatsapp:008615052325696

E-posta:tzxinyue@gmail.com

XinYue Çin

XinYue Çin

Whatsapp

Bizimle bir WhatsApp sohbeti başlatmak için QR kodunu tarayın.