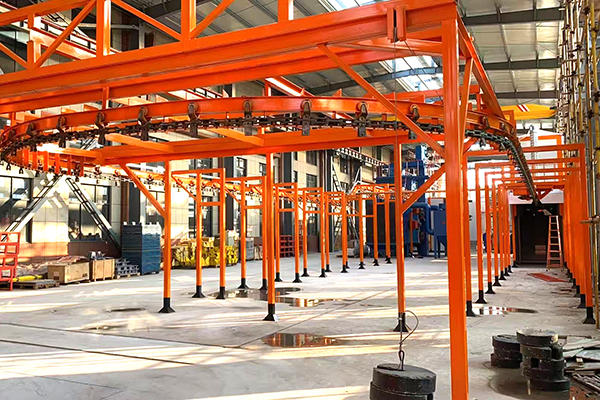

horizontal powder coating line manufacturer

Exported to more than 60 löndum um allan heim

Meet different customer needs

The core advantages of horizontal powder coating line design

1、The dufthúðunarlína process is uniquely designed, with high coating uniformity, no grooves, no impurities, no peeling, and stable quality.

2、The automatic powder coating system is highly efficient and reduces labor/time costs.

3、The powder coating reclaim system has a recovery rate of 98.9%, and the powder is recycled, which is environmentally friendly and energy-saving.

powder coating line price

Prices start at $6,000!

Powder coating line prices are determined by the following factors:

1、The maximum size of the workpiece:

determine the cross-sectional area size of the powder room and drying channel.

2、Weight of the workpiece:

determines the selection of the chain, light weight: 30, 50, 100 kg; Heavy duty: 250, 500 kg.

3、Output of spraying:

determines the length of the spraying line.

4、Óstöðluð aðlögun:

The price is determined according to the length, width, and height of the customer's factory, as well as whether the pre-treatment is online.

Thank you for your consultation! Please provide the following information in the form below:

1.What is the maximum size of the workpiece?

2.What is the production volume?

3.How big is the workshop area?

Please share your WhatsApp or other instant tools for more timely communication!

Velkomin vinir frá öllum heimshornum til að heimsækja verksmiðjuna okkar

Í nútíma verkstæði meira en 24,000 fermetrar, stöðlun liggur í gegnum allan framleiðslutengilinn.

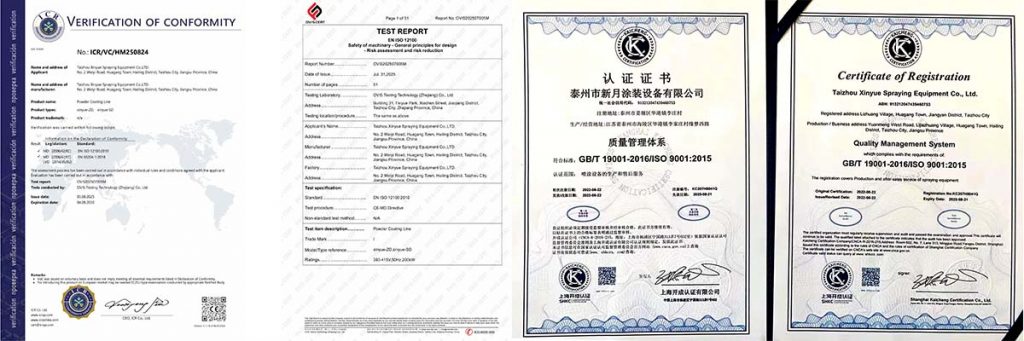

Mörg gæðaeftirlitspróf til að ná "framleiðslustaðla, rekjanleika ferla, og gæðatryggingu" til að tryggja háar gæðakröfur.

Við höfum 33 ára reynslu í iðnaði og útflutningur til meira en 60 löndum um allan heim.

Ítalskir verkfræðingar eru staðsettir í verksmiðjunni til að fá leiðsögn, þjóna mörgum stórum fyrirtækjum.

Framtaksandi:

heilindi, þakklæti, einingu, vinnusemi

Verkefni fyrirtækja:

gera aðgerðina einfaldari og gera málverkið hagkvæmara

Fyrirtækjasýn:

að verða kínverskt húðunarfyrirtæki sem er verðugt trausts heimsins!

XinYue Kína

XinYue Kína

WhatsApp

Skannaðu QR kóðann til að hefja WhatsApp spjall við okkur.