pećnica

Through precise temperature control and efficient thermal cycling, it ensures that the sprayed workpiece surface forms a uniform and strong adhesion coating.

3 core advantages

1.Improve coating quality

High temperature uniformity, stable curing effect, avoid bubbles, orange peel patterns, sagging and other defects, and ensure that the coating adhesion, hardness, corrosion resistance and other properties meet the standards.

2.Increase production efficiency

Shorten the curing cycle, adapt to mass production, and reduce manual dependence.

3.Energy-saving technology reduces costs

Saving energy consumption and long-term use can significantly reduce operating costs.

Oven price

The price varies depending on the specifications, materials, functions and other factors, and is not a standard customization.

Hvala vam na savjetovanju! Molimo unesite sljedeće podatke u donji obrazac:

1) What’s the maximum & minimum size of workpiece( LxWxH)?

2) What’s the maximum weight of workpiece? If possible,youd better share us product photos.

3) How many workpiece do you want to paint per day( 8hrs or 16hrs ) or per month ?

4) What kind of heating energy do you prefer, such as electricity, diesel, oil, or natural gas?

5) What’s your workshop size LxWxH? May we have a drawing of your workshop?

6) Before painting, do you need spray pretreatment to clean the surface of product?

7) What’s the voltage & frequeny in your country?

Molimo podijelite svoje WhatsApp ili drugi instant alati za pravovremeniju komunikaciju!

Dobrodošli prijatelji iz cijelog svijeta da posjete našu tvornicu

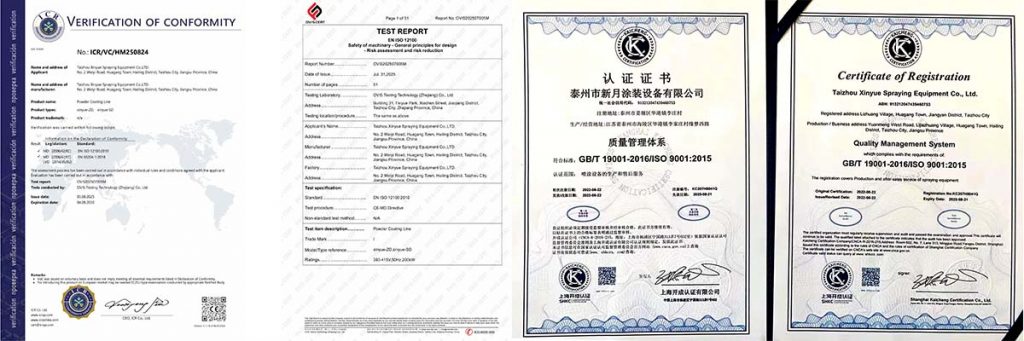

U suvremenoj radionici od više od 24,000 četvornih metara, standardizacija prolazi kroz cijelu proizvodnu vezu.

Višestruki testovi kontrole kvalitete za postizanje "proizvodni standardi, sljedivost procesa, i osiguranje kvalitete" kako bi se osigurali zahtjevi visoke kvalitete.

imamo 33 godina iskustva u industriji i izvoza u više od 60 zemalja širom svijeta.

Talijanski inženjeri stacionirani su u tvornici radi usmjeravanja, služeći mnogim velikim poduzećima.

Poduzetnički duh:

integritet, zahvalnost, jedinstvo, naporan rad

Korporativna misija:

pojednostaviti rad i učiniti bojanje isplativijim

Korporativna vizija:

postati kinesko poduzeće za premaze vrijedno povjerenja svijeta!

Kontaktirajte nas

Telefon:+0086-17802529388

Wechat:17802529388

WhatsAPP:008615052325696

E-mail:tzxinyue@gmail.com

XinYue Kina

XinYue Kina

WhatsApp

Skenirajte QR kod da započnete WhatsApp chat s nama.